1. Steps (Mold Manufacturing Process)

The production of injection molds typically follows the following core steps:

1.1 Product Design & Analysis

(1) Receiving Data: Obtain 3D/2D models and dimensions of plastic products from customers (usually in formats such as STP and IGES).

(2) Feasibility Analysis: Check whether the product structure is suitable for injection molding production (e.g., wall thickness uniformity, draft angle, undercut, reinforcing rib, etc.).

(3) Mold Flow Analysis: Use CAE software (such as Moldflow) to simulate the filling, holding, and cooling processes of plastic in the mold, predict potential defects (sink marks, gas marks, warpage, etc.), and optimize the gate position and cooling system.

1.2 Mold Design

(1) Determine Parting Line: Define the interface between the moving mold and fixed mold of the mold, which is the core of mold design.

(2) Cavity Layout: Decide the number of cavities per mold (e.g., 1-cavity, 4-cavity, etc.) based on production volume requirements.

(3) Design Core Systems:

① Feed System: Design the sprue, runner, and gate to ensure smooth filling of the mold cavity with plastic melt.

② Ejection System: Design ejector pins, sleeves, ejector plates, etc., for smooth ejection of the product after molding.

③ Cooling System: Design water channels to ensure rapid and uniform cooling of the mold, shortening the cycle time.

④ Venting System: Create vent grooves to avoid gas trapping, which may cause burning or incomplete filling.

(4) Design Structural System: Select the mold base and design guide pins, screws, support pillars, etc.

(5) Special Structure Design: If there are undercuts, design core-pulling structures such as slides and lifters.

(6) Output Drawings: Generate detailed part processing drawings and assembly drawings.

1.3 Material Procurement & Preparation

(1) Purchase Mold Steel: Procure mold steel (e.g., P20, H13, S136). Its hardness, wear resistance, and corrosion resistance should be selected according to product requirements.

(2) Purchase Standard Parts: Procure standard parts (mold base, ejector pins, screws, guide pins, etc.).

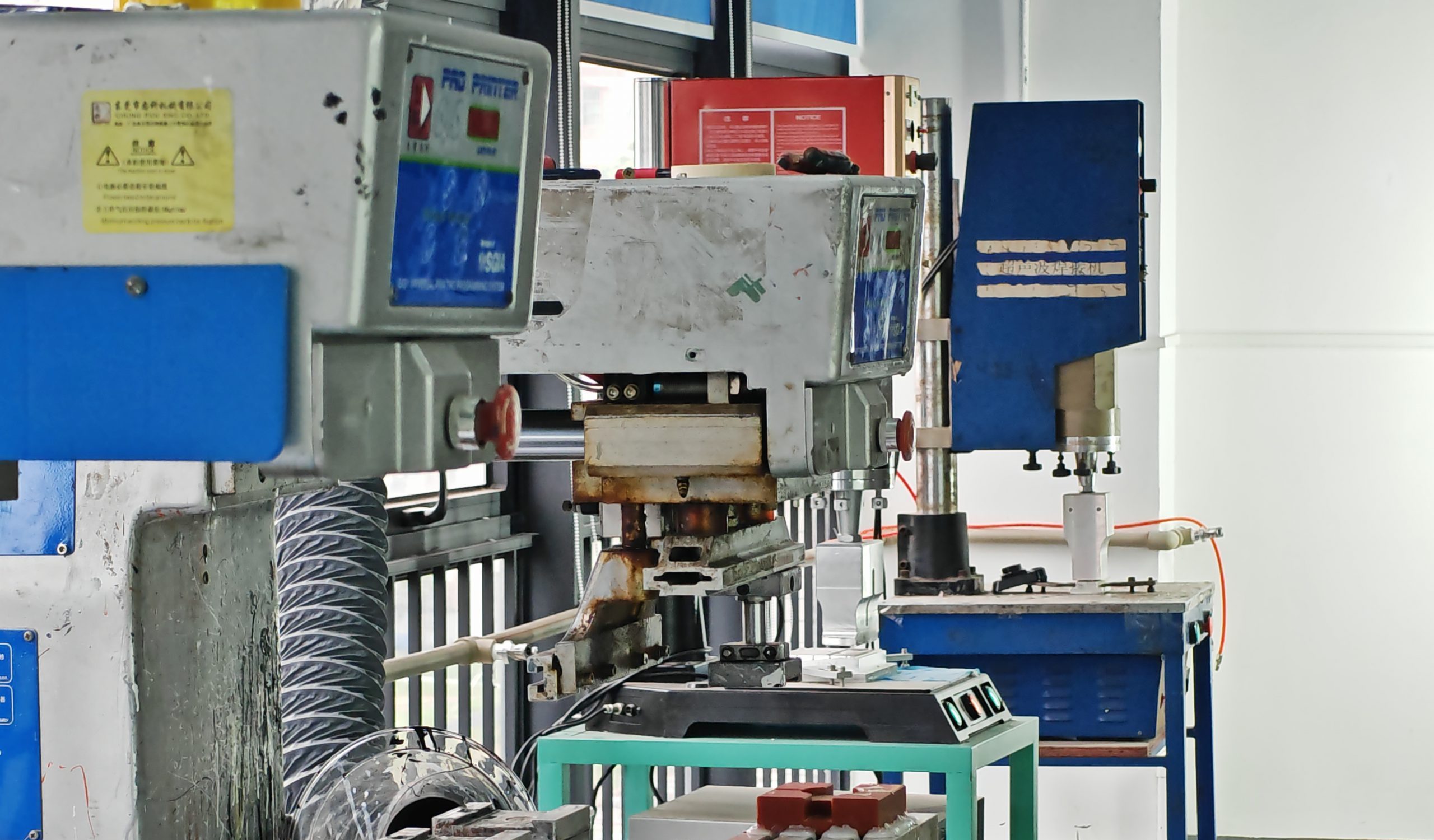

1.4 Component Machining

(1) Rough Machining: Use milling machines, lathes, etc., to remove most of the material allowance.

(2) Heat Treatment: Perform quenching, nitriding, and other treatments on core components (e.g., mold inserts, slides) to improve surface hardness and wear resistance.

(3) Precision Machining:

① CNC Milling/Engraving: Use high-speed CNC machine tools for high-precision surface machining.

② EDM (Electrical Discharge Machining): Used for machining deep grooves, sharp corners, and complex textures that are difficult to achieve with CNC.

③ WEDM (Wire Electrical Discharge Machining): Mainly used for machining inserts, holes, and precision straight structures.

(4) Grinding: Ensure the parallelism, perpendicularity, and precise dimensions of the parts.

1.5 Assembly & Trial

(1) Fitting: Assemble all machined parts into a complete mold according to the design drawings.

(2) Trial Shot: Install the mold on the injection molding machine and conduct actual injection testing.

(3) Inspection & Adjustment: Check whether the size and appearance of the samples produced during the trial shot meet the requirements. Adjust process parameters or modify the mold (e.g., adjust water channels, polish, modify gate size, etc.) based on any issues identified.

(4) Mold Acceptance: The process is completed only when the samples are fully qualified and the customer confirms the sample by signing off.

1.6 Mass Production & Maintenance

(1) Put the Mold into Formal Mass Production: Deploy the mold for official large-scale production.

(2) Regular Maintenance: Conduct regular maintenance, including cleaning, rust prevention, and replacement of vulnerable parts, to extend the mold service life.